р

(

ρ

)

(1) can be written as

c

0

=

p

nA/ρ

0

which allows linking the

coefficients

A

and

n

:

A

=

ρ

0

c

2

0

/n

. So the equation (1) can be rewritten as:

p

=

ρ

0

c

2

0

n

ρ

ρ

0

n

−

1

,

where there is the only unknown coefficient

n

. This coefficient was selected

in case if a deviation of equation (1) from compressibility equation (2) of

the multicomponent material containing tungsten, nickel, and iron in the

given ratio is minimal. A pressure range was considered from 0 to 40 GPa

which overlapped the domain of pressures occurring during the material

interactions at velocities of 1000. . .2000 m/s.

In the end, to perform these numerical computations the dynamic

compressibility equation (1) with coefficients

A

= 57

.

1

GPa;

n

= 4

.

7

was

used. The contrastive analysis of the different dynamic compressibility

curves of the observed material showed that equation (1) with the given

values of the coefficients resulted in the similar way as the ones obtained

by equation (2) for a multicomponent medium.

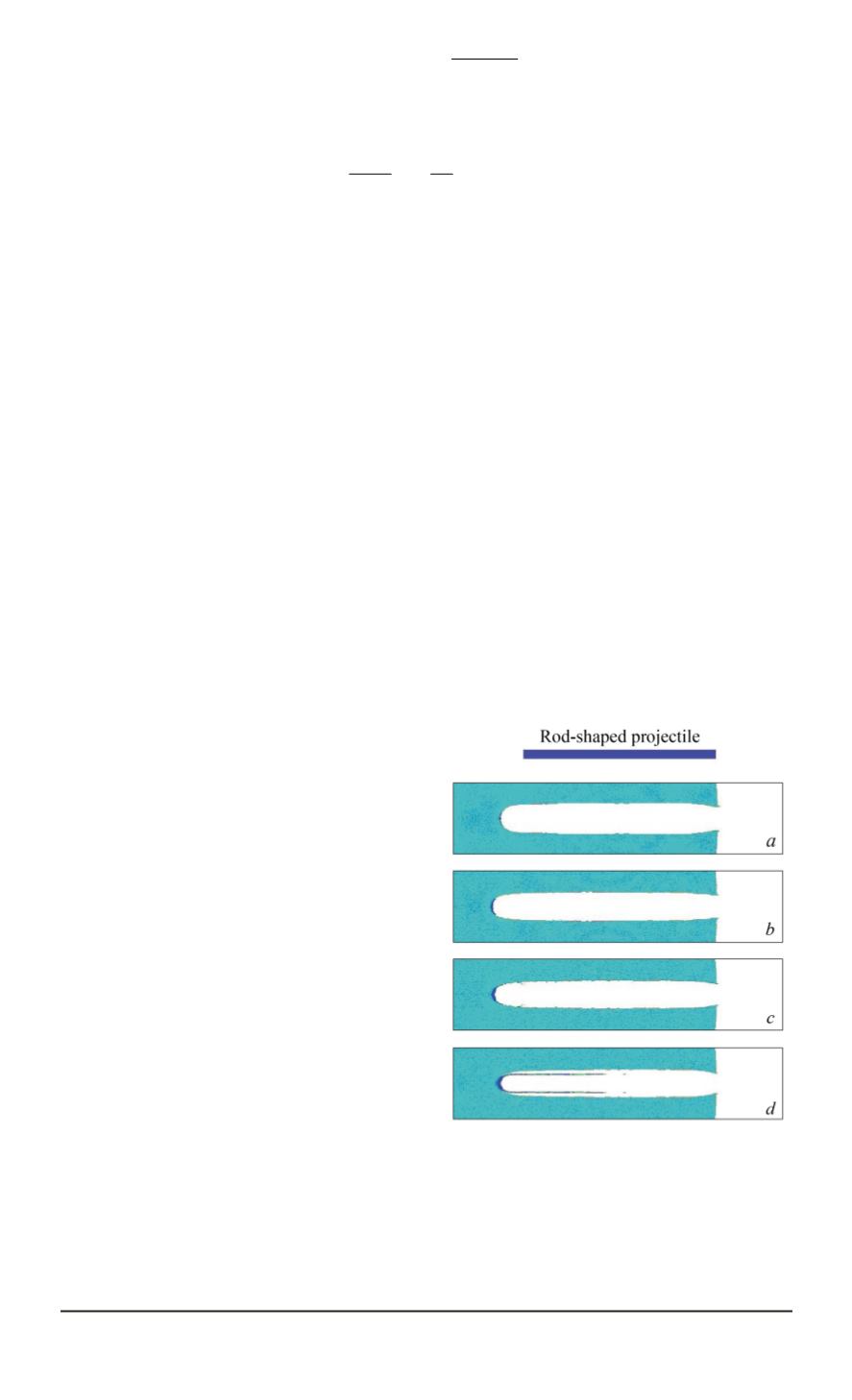

The numerical computations were performed for a cylinder shaped

projectile made of VNZh-90 alloy with the length of

l

0

= 500

mm and

a diameter of

d

0

= 24

mm (elongation of

l

0

/d

0

≈

21

). The target was

assumed to be made of steel with the strength corresponding to the steel

Рис. 2. Steel target cavity shape during

the penetration of VNZh-90 alloy

elongated projectiles with different yield

strengths at initial interaction velocity of

1600m/s:

a

—

d

—

σ

Y

= 50

; 500; 1000; 1500MPa,

respectively

targets of a medium hardness (a

yield strength was set 1000MPa).

Dynamic compressibility of the steel

target was defined by equation (1)

with the coefficients

A

= 19

.

5

GPa;

n

= 5

.

642

[18]. Target thickness was

800 mm and its lateral size (diameter)

was 320 mm.

While analyzing the impact of

the projectile material strenght on the

target penetration, its yield strength

σ

Y

was taken to be equal to 50; 500;

1000, and 1500MPa.

Fig. 2 shows the final shapes

of the cavities in the steel targets

obtained during the penetration

of the elongated rods made of

VNZh-90 alloy with different yield

strengths and the initial interaction

velocity

v

0

= 1600

m/s. The results

ISSN 0236-3941. HERALD of the BMSTU Series “Mechanical Engineering”. 2015. No. 1 73