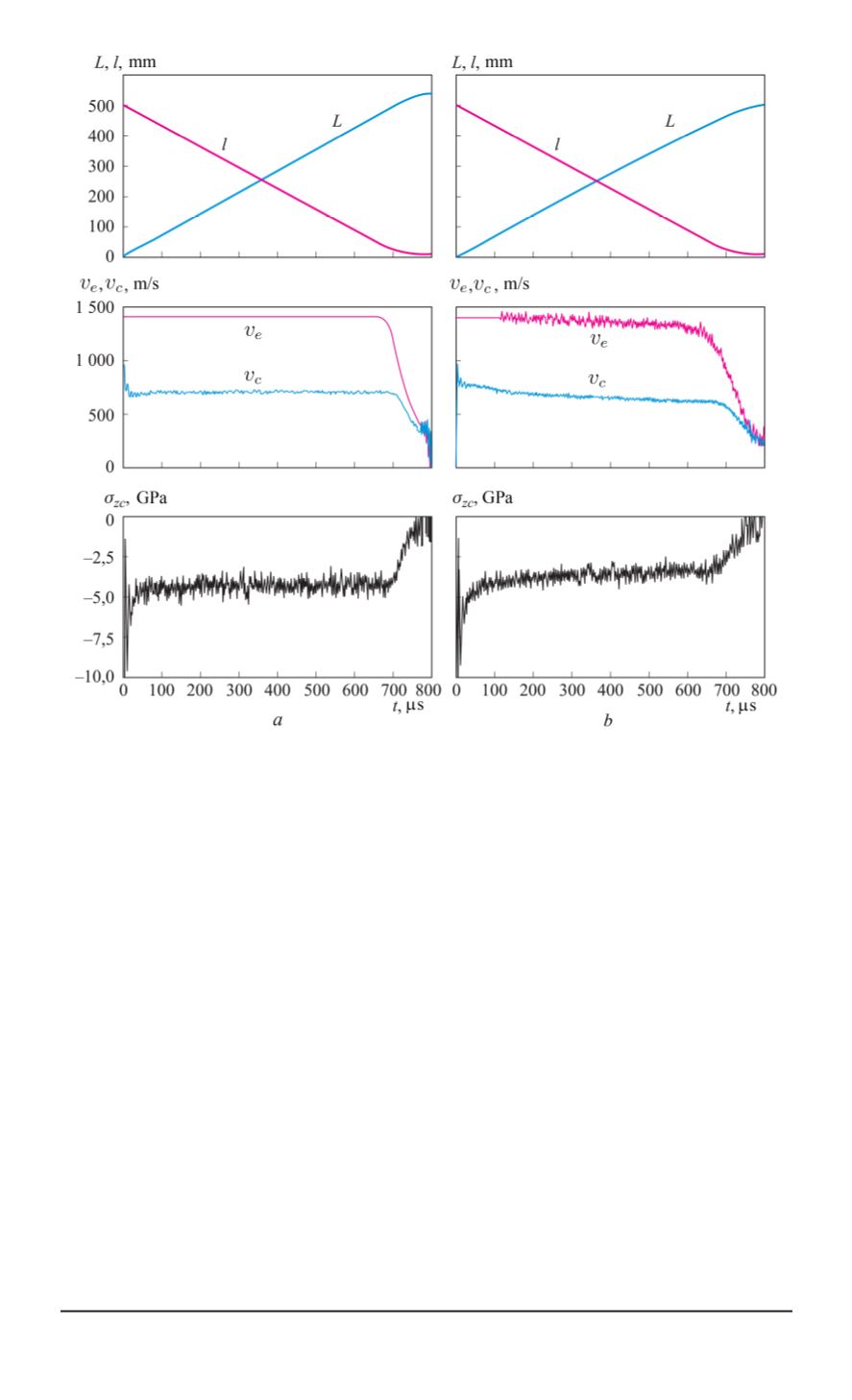

Fig. 5. Change of the parameters during the steel target penetration by the VNZh-

90 alloy rod with the yield strength of 50MPa (

a

) and 1500MPa (

b

) at the initial

interaction velocity of 1400m/s

cases a hydrodynamic penetration mode occurs when the projectiles “wear

away” completely as a result of their material spreading along the contact

boundary of the cavity formed in the target.

Fig. 5 and 6 illustrate the dynamical penetration of the VNZh-90 alloy

elongated projectiles used in the computations. It is illustrated by a time

ratio of the penetration depth

L

, a projectile current length

l

, a projectile

trailing end velocity

v

e

, a penetration velocity

v

c

, and an axial stress

σ

zs

on the contact border of the target constructed for the following

projectile initial velocities

v

0

and yield strength

σ

Y

values:

v

0

= 1400

m/s,

σ

Y

= 50

MPa (Fig. 5,

a

);

v

0

= 1400

m/s,

σ

Y

= 1500

MPa (Fig. 5,

b

);

v

0

= 2000

m/s,

σ

Y

= 1000

MPa (Fig. 6).

Comparison of the data in Fig. 5 shows a significant difference between

a dynamical behavior of the penetration parameters for the projectile with

a minimum strength (

σ

Y

= 50

MPa, see Fig. 5,

a

) and for a projectile with

a very high strength (

σ

Y

= 1500

MPa, see Fig. 5,

b

) at the same initial

velocity.

ISSN 0236-3941. HERALD of the BMSTU Series “Mechanical Engineering”. 2015. No. 1 77