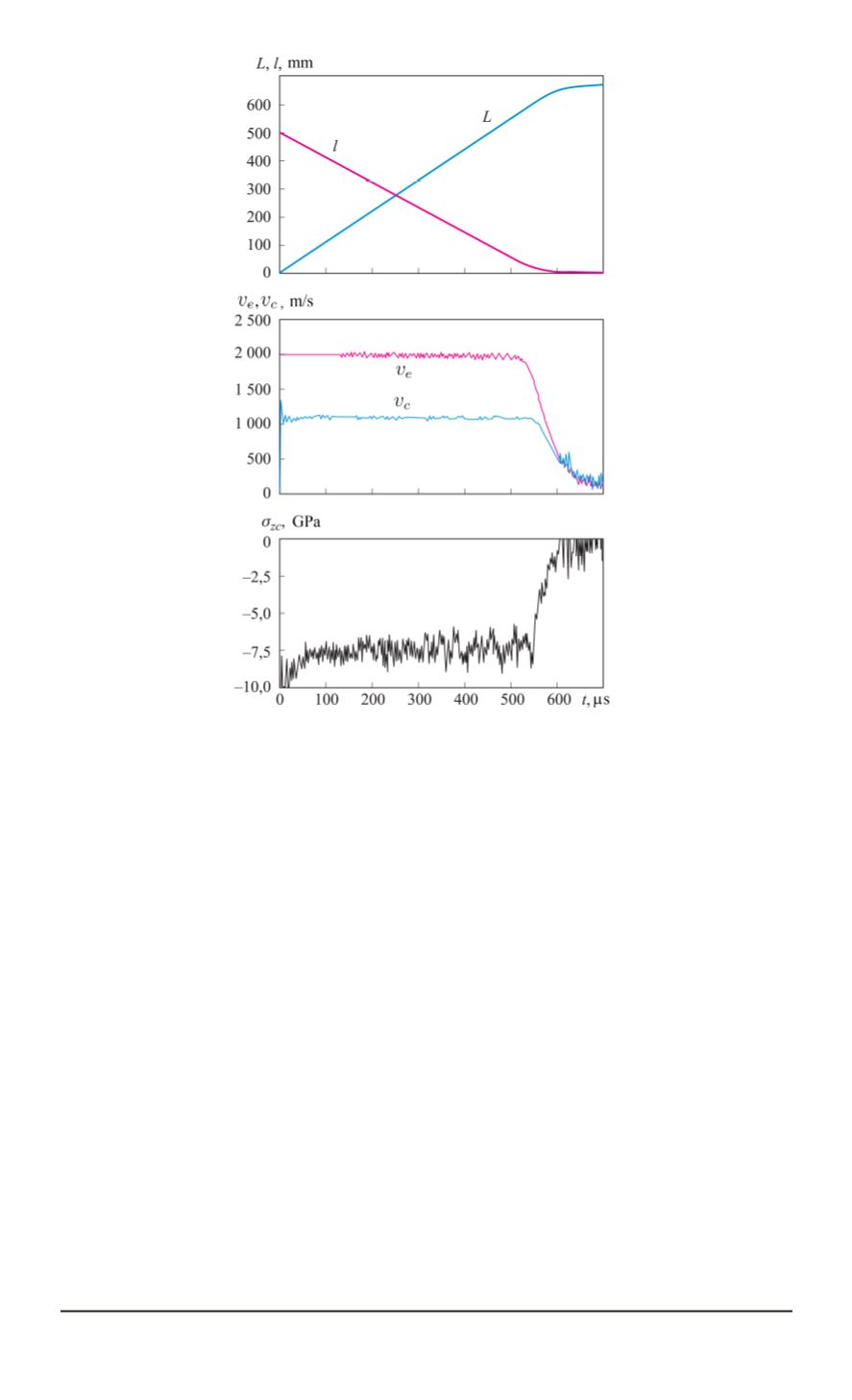

Fig. 6. Change of parameters during the steel target penetration of the VNZh-90

alloy rod with the yield strength of 1000MPa at the initial interaction velocity of

2000m/s

Both the projectile trailing end velocity

v

e

and the steel target contact

boundary velocity

v

c

of a low strength projectile remain constant during

the whole penetration process. Their values drop to zero only at the very

moment when the projectile length reduces to the value close to its diameter

(see Fig. 5,

a

). On the contrary, in the case of a high-strength projectile

there is a visible reduction of the velocities

v

e

and

v

c

at the early stages

of the process (see Fig. 5,

b

). This fact correlates with the Alekseyevsky –

Tate rod-shaped projectile penetration model [4, 5]. Velocity reduction of

the remaining part of the high-strength projectile during the penetration

results in reducing contact stresses

σ

zc

while contacting with the target (see

Fig. 5,

b

). For a low-strength projectile these stresses remain approximately

constant up to the moment when the projectile length becomes zero

(see Fig. 5,

a

). The performed analysis highlights physical factors, which

cause a higher penetration effect when a projectile with the yield strength

σ

Y

= 50

MPa is used comparing to a projectile with the yield strength

σ

Y

= 1500

MPa at the interaction velocity

v

0

= 1400

m/s.

78 ISSN 0236-3941. HERALD of the BMSTU Series “Mechanical Engineering”. 2015. No. 1