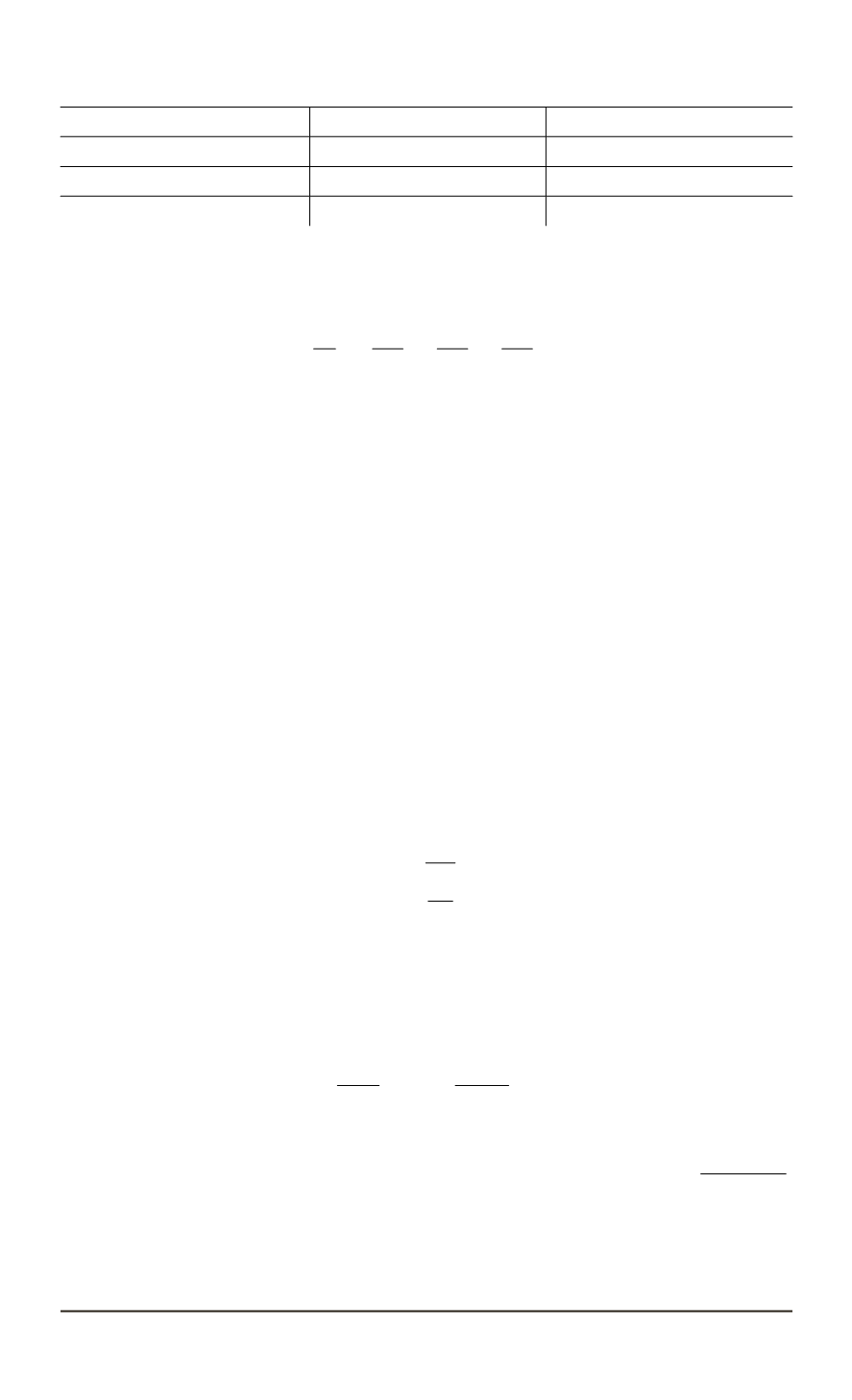

Empirical coefficients in the compressibility equations of tungsten – nickel – iron

heavy alloy components

Material

A

, GPa

n

Tungsten

94.6

3.42

Nickel

45.3

4.507

Iron

19.5

5.642

elongated projectile. The density

ρ

0

of this alloy was

ρ

0

= 17170

kg/m

3

at

normal conditions. It was calculated by the formula

1

ρ

0

=

μ

1

ρ

10

+

μ

2

ρ

20

+

μ

3

ρ

30

.

Volume densities

ρ

i

in VNZh-90 alloy which are needed for drawing

a curve of the alloy dynamic compression (2) were calculated by the

equations

α

i

=

μ

i

ρ

0

/ρ

i

0

. They had the following values:

α

1

= 79

.

9

%

(for tungsten);

α

2

= 13

.

5

% (for nickel); and

α

3

= 6

.

6

% (for iron).

The obtained equation of the dynamic compressibility for VNZh-90

alloy in the form of equation (2) doesn’t allow developing an explicit

equation of the pressure

p

inside the material as a function of its density.

It makes this equation impossible to use for a numerical simulation (as

it is necessary to construct a special procedure for calculating pressure

based on this relationship; it results in increasing the computational time

significantly).

To solve this problem, equation (2) was approximated by the compressi-

bility equation (1); the coefficients

A

and

n

were selected respectively. In

order to determine these coefficients, the speed of sound in the alloy at

normal conditions was calculated.

c

0

=

s

dp

dρ

p

=0

.

When the function

p

(

ρ

)

is used in the form of equation (2),

c

0

is calculated

using the following equation:

1

ρ

0

c

2

0

=

3

X

i

=1

α

i

ρ

i

0

c

2

i

0

,

here

c

i

0

— are the speeds of sound in the alloy components at normal

conditions which are calculated on the basis of (1) as

c

i

0

=

p

n

i

A

i

/ρ

i

0

.

Calculation of the speed of sound inside VNZh-90 alloy at normal

conditions resulted in a value

c

0

= 3950

m/s. On the other hand, the

expression of

c

0

which uses the approximating compressibility equation

72 ISSN 0236-3941. HERALD of the BMSTU Series “Mechanical Engineering”. 2015. No. 1