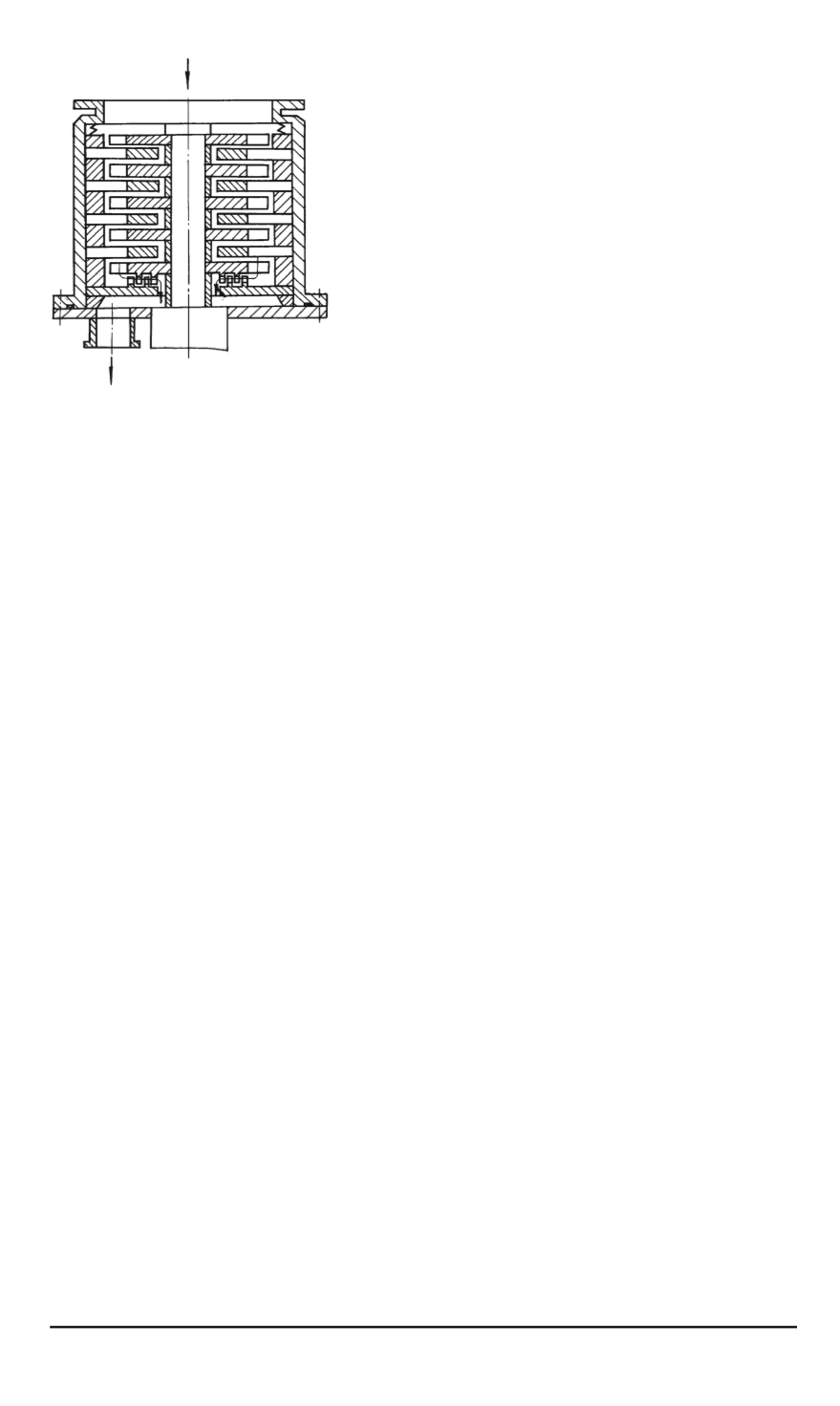

Рис. 4.

TMP design

arrangement with a hybrid flow

channel

TMPs with a variable flow and

without stator wheels have been designed.

This allows pumping gases with solid

macro particles. It is very important

for various sputtering units. One of the

pump modifications is shown in Fig. 3,

b

.

A peculiar feature of this design is a

combination of rotor wheels with alternating

axial and radial gas flows in the pump flow

channel. As a result, the efficiency of each

stage is increased.

TMP dimensions can be reduced if the

rotor wheels with a radial gas flow are

positioned on the pressure side (Fig. 4).

The research demonstrates that this

design arrangement has significant possibilities, especially with the multi

parametric optimization of TMP main characteristics.

The pressures ratio can be increased without increasing the pump

dimensions, if TMP axial stages and a cylindrical molecular vacuum pump

(MVP) unit are coupled in the flow channel.

In Fig. 5 TMNG-500 (variant 1) and TMNG-450 (variant 2) are

presented in comparison. TMNG-500 flow channel contains a conventional

set of both the axial rotor and stator blade wheels; in TMNG-450 it contains

blocks of the axial blade wheels and a cylindrical molecular pump with

helical channels in the pump casing. The shaft of these pumps is mounted

onto two radial and one axial aerostatic bearings.

TMNG-500 development was determined by the need to verify the

data for the efficiency of the hybrid flow channel designs and to estimate

manufacturing hours compared to TMN-450 pump, the flow channel of

which contains both the axial stages and molecular stages unit.

After comparing the mass produced vehicles it was established that with

25% increase in the agility reference value, both the volume and mass of

TMNG-500 pump grow by 20% and 6%, correspondingly compared to

TMNG-450 pump. Apart from that, according to the Special Design and

Engineering bureau

Vector

the production costs of these models include 862

(TMNG-500) and 950 (TMNG-450) standard hours, correspondingly. All

of this testifies to the superiority of the hybrid flow channel pumps, as they

possess the improved dimensional characteristics accounting for a certain

complexity in manufacturing. This is also confirmed by the sustained trend

of the world’s leading manufacturers to increase the number of vacuum

TMP with the hybrid flow channel (with the axial and molecular stages)

[4–8].

6

ISSN 0236-3941. HERALD of the BMSTU. Series Mechanical Engineering. 2014. No. 5