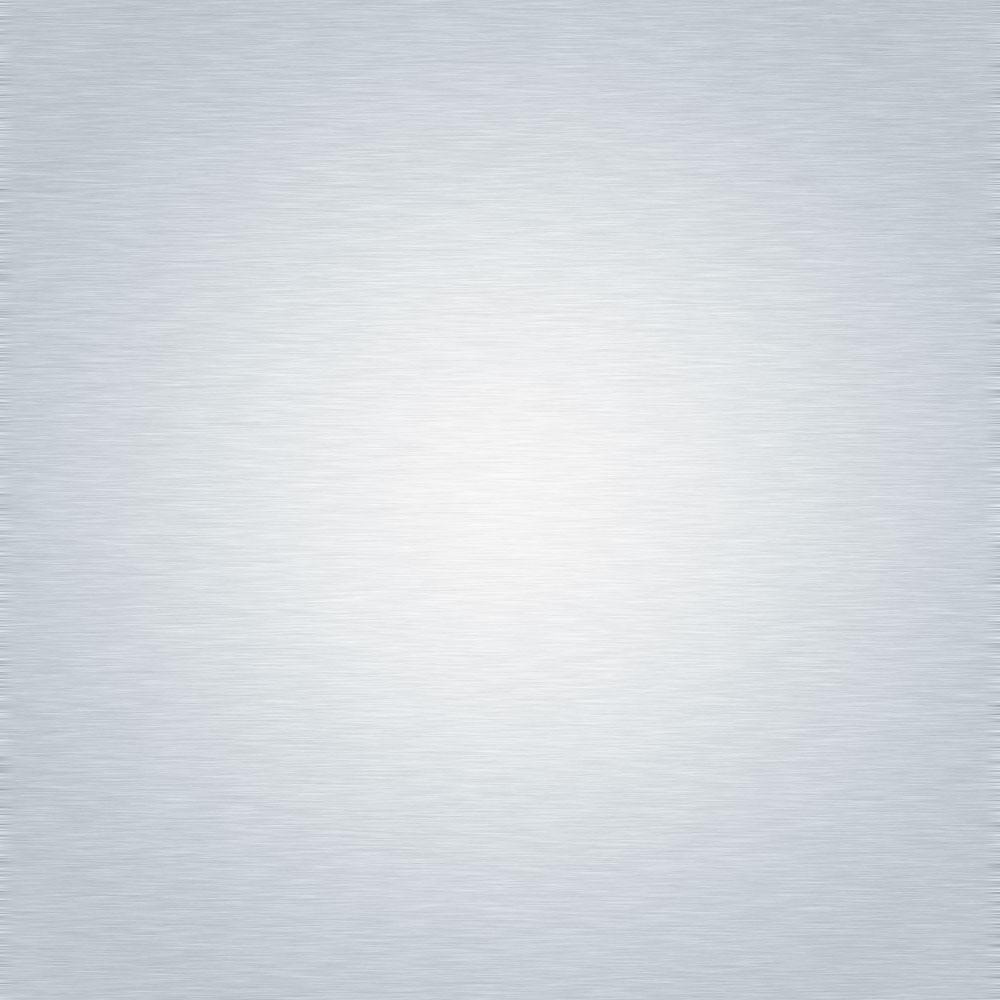

Fig. 2. TMP structural scheme with gas

reversing (

a

) and frontal radial blade

on stator wheels (

b

)

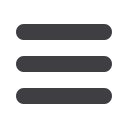

Fig. 3. HVMP design arrangements with

adsorption pumps on the pressure side

(

a

) and axial and radial gas flow in the

rotor (

b

)

Another perspective trend of HVMP improvement consists of combining

TVP elements with other types of high-vacuum pumps based on different

operating principles in the flow channel.

A TMP design arrangement (Fig. 3,

a)

was suggested with an adsorbent

located in special cavities of the exit stator wheels. This enables additional

gas evacuation in these wheels. To increase the gas absorption efficiency,

these wheels (located on the pressure side) are cooled up to 80. . . 100 K

with liquid nitrogen fed into a special cooling jacket in a special vacuum

chamber. This flow channel arrangement eliminates the need to use oil fore

pumps for the initial vacuum when putting the pump into operation with

the help of the atmospheric pressure, as this function will be performed by

an adsorbent. Moreover, the adsorbent regeneration will be realized without

stopping the TMP and disengaging it from the pumping system.

It is known that TMP should not be used for gas media containing solid

macro particles without special protection since it results in the degradation

of pump parameters.

ISSN 0236-3941. HERALD of the BMSTU. Series Mechanical Engineering. 2014. No. 5

5