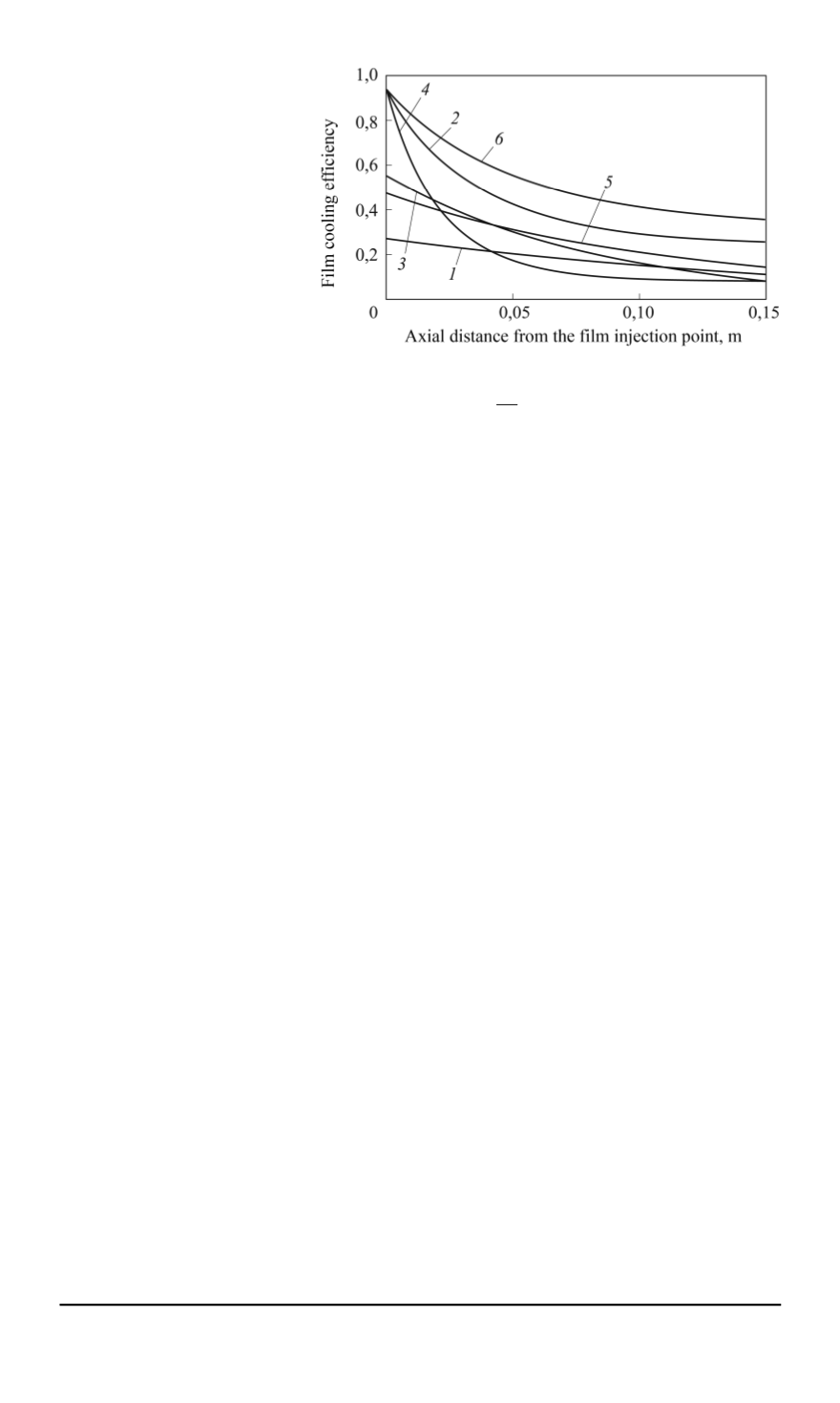

Fig. 3. Influence of coolant

mass flow-rate on film

cooling efficiency [9]:

1, 3

and

5

— nitrogen,

m

f

= 6

, 11 and 15%;

2, 4

and

6

— kerosene,

m

f

= 9

,

5 and 14% respectively

pressure

p

k

= 2

MPa and the constant mixture ratio

K

m

= 3

.

2

. The

value of the coolant relative mass flow-rate

˙

m

f

varied from 0.05 to 0.15.

The results prove that the higher the coolant relative mass flow-rate is,

the higher the film cooling efficiency becomes. With the distance from

the coolant injection point increasing, the cooling efficiency gradually

decreases (Fig. 3)

Special attention should be paid to [10]. This paper considers the

thermal state of the RE combustion chamber walls working on gaseous

СН

4

+ О

2

, H

2

+ O

2

, and CO + O

2

propellant combination. Such engines

feature a new cooling method, so called “vortex cooling”. The method is

essentially the following: the whole amount of oxidizer used as a coolant is

fed into the combustion chamber not via a mixing unit but through cyclonic

ports located in the cylindrical axisymmetric segment of the chamber. This

cyclic injection results in forming a coolant vortex along the combustion

chamber wall, which restrains the combustion within the chamber core

unit, thus reducing the heat transfer to the wall surfaces. In its turn, the fuel

is injected via a mixing unit and is entrapped into the oxidant vortex flow

in the chamber, forming an internal vortex where the combustion occurs.

The general layout of this engine is shown in Fig. 4.

A transparent acrylic segment of the combustion chamber was used

to visualize the flow for this cooling method during the hot starts. Fig. 5

presents an image of the cylindrical combustion chamber in the process

of H

2

+ O

2

combustion with

K

m

= 6

mixing ratio and

p

k

≈

0

.

9186

MPa

chamber pressure. Information for the scale: the external diameter of the

chamber acrylic segment is 0.09 m.

According to Fig. 5 the combustion zone is restricted within the

chamber internal area, a ring of cold gas separates the wall inner surface

from the combustion zone.

A series of two-second hot starts was performed. The test results show a

high efficiency of engines performance. For instance, for the H

2

+ O

2

rocket

engine specific impulse constituted 97% of the one theoretically possible

ISSN 0236-3941. HERALD of the BMSTU. Series “Mechanical Engineering”. 2014. No. 1 85