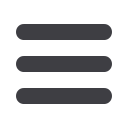

Fig. 2. Pressure sensor readings at the nozzle unit entrance

Fig. 3. Pressure sensor readings in the shock tube

initial shockwave. At approximately 300 ms before the shockwave reflected

from the right end wall (fragment

1a

in the oscillogram, Fig. 2) the gas

following the head shockwave passes through the cross-section where the

sensor is located. The phase in question is closely studied by means of

numerical simulation in [10], where the structure of the flow following

the reflected shockwave front was investigated under shock tube tests

conditions. The subsequent sharp increase in pressure (

2

, Fig. 2) and the

smooth decrease (

3

, Fig. 3) to the fluctuating values indicate the shock wave

reflected from the nozzle end wall and the quasi steady flow parameters

(about 10 ms) before the rarefaction wave.

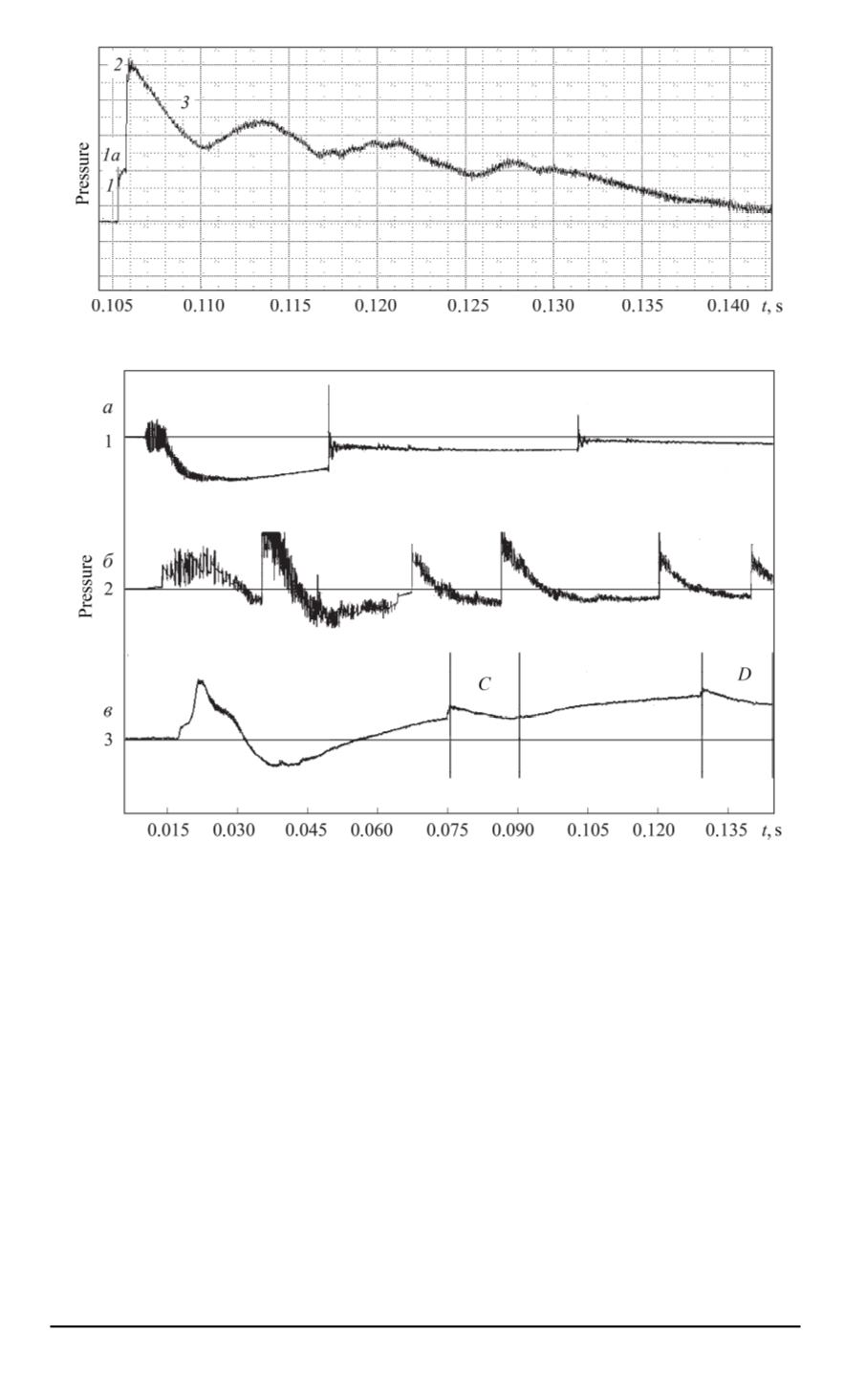

The oscillograph patterns of the pressure sensors located in various

areas of the shock tube are presented in Fig. 3. The test initial conditions

were the same as in Fig. 2. The top graph indicates the pressure for the

ISSN 0236-3941. HERALD of the BMSTU. Series “Mechanical Engineering”. 2015. No. 1 7