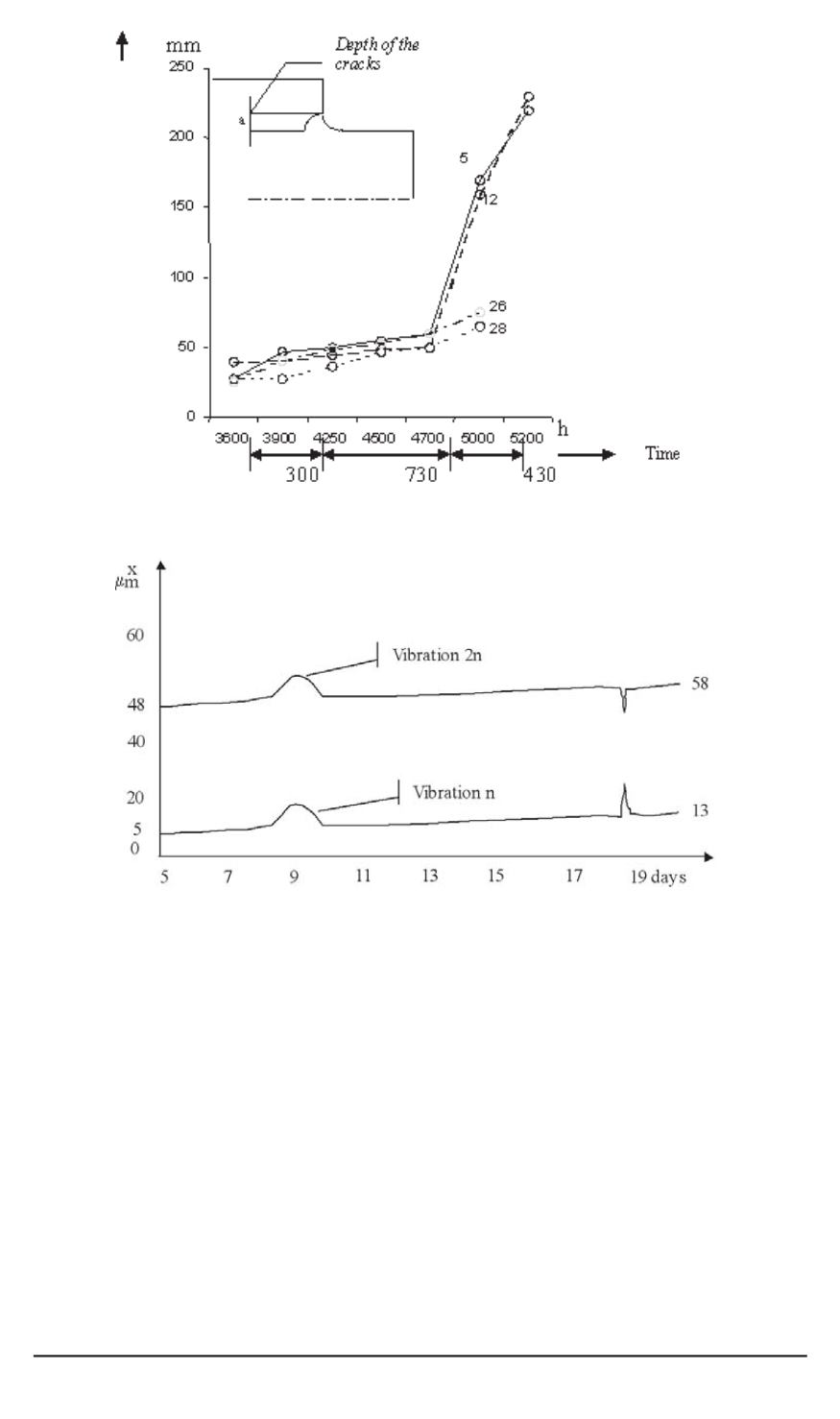

Fig. 8. Depth of the cracks as the function of work duration

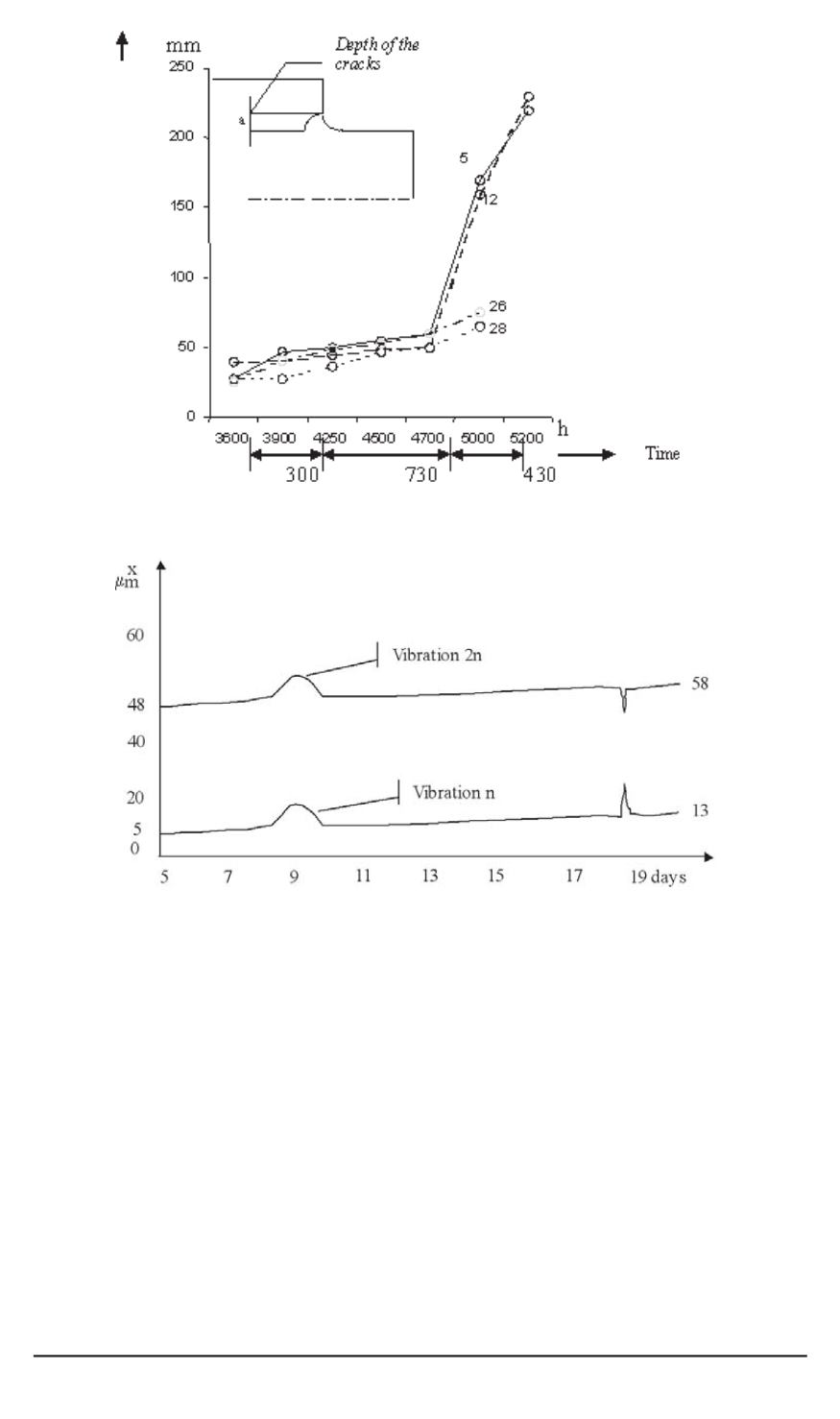

Fig. 9. The vertical vibrations of generator shaft on the exciting side

revolutions. Rotor grazed several gaskets. Besides, that rotor could revolve

for further 30 hours but it was observed that it was distorted for 2.5 mm.

When it was stopped, a crack was found, which was about 98 mm from the

bearing impulsive side and expanded for half of the perimeter. When the

surface of the crack was opened, it was found that half of the cross section

was broken (Fig. 12).

As a result it is was confirmed that vibrational behaviour shown in

Figs. 10 and 11 is characteristic of the rotor with cracks but there is no

assurance that cracks exist in the rotor if it behaves like that. Further

informations are given by the curve of shutting down (Fig. 13). They show

behaviour of this turbogenerator when it was shut down after 50 days and

12 days before it was put out of work. It was observed that for the last 12

days critical number of revolutions

n

2

/

2

moved from 950 to 960 and that

116 ISSN 0236-3941. Вестник МГТУ им. Н.Э. Баумана. Сер. “Машиностроение”. 2009. № 3