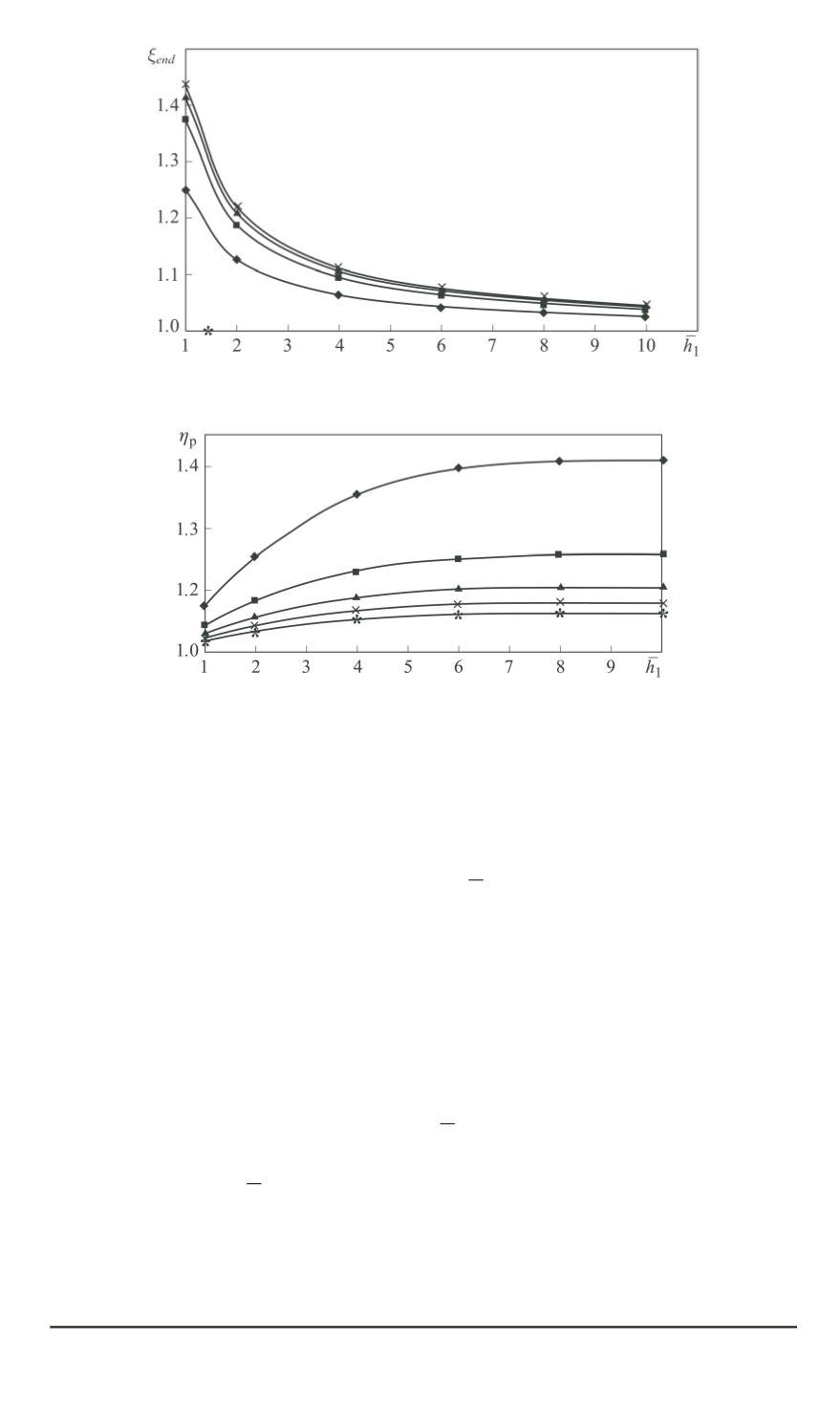

Fig. 4. Dependency of fins end surfaces contribution on finning parameters

ˉ

t

ˉ

t

ˉ

t

:

—

t

= 2

; —

t

= 4

;

N

—

t

= 6

;

×

—

t

= 8

Fig. 5. Dependency of the finning coefficient

η

p

on CC finning parameters with

accounting for the fins end surfaces at Bi = 0.04:

—

t

= 2

; —

t

= 4

;

N

—

t

= 6

;

×

—

t

= 8

;

∗

—

t

= 10

The dependency of

ξ

end

coefficient on finning parameters is shown in

Fig. 4.

With the account for

ξ

end

influence, the finning coefficient

η

f

increases

markedly in the fins low height area (

h

1

= 1

. . .

4

), then it tends to

stable values while increasing simultaneously, with the pitch value growing

(Fig. 5). With the Biot number increasing, the finning coefficient markedly

decreases.

The pattern of change of the combined thermal geometrical parameter

A

∗

=

A

f

η

f

(Fig. 6) has the following implications. As it was expected,

the pattern of

A

∗

change corresponds to the full-size finning with regards

to the fins height, however, its absolute value is 15. . . 30% lower mostly

due to considering only the fins height

h

1

on the heat realing surface while

calculating the finning coefficient. The maximum of its values shifts to the

large-values region

h

1

, which extends the optimal finning parameters zone.

In all other cases, HTI in CC can be calculated and analysed according

to the above presented methodology for the circular finned channels [1]

taking into account their specific factors, parameters and features of coupled

50

ISSN 0236-3941. HERALD of the BMSTU. Series Mechanical Engineering. 2015. No. 2