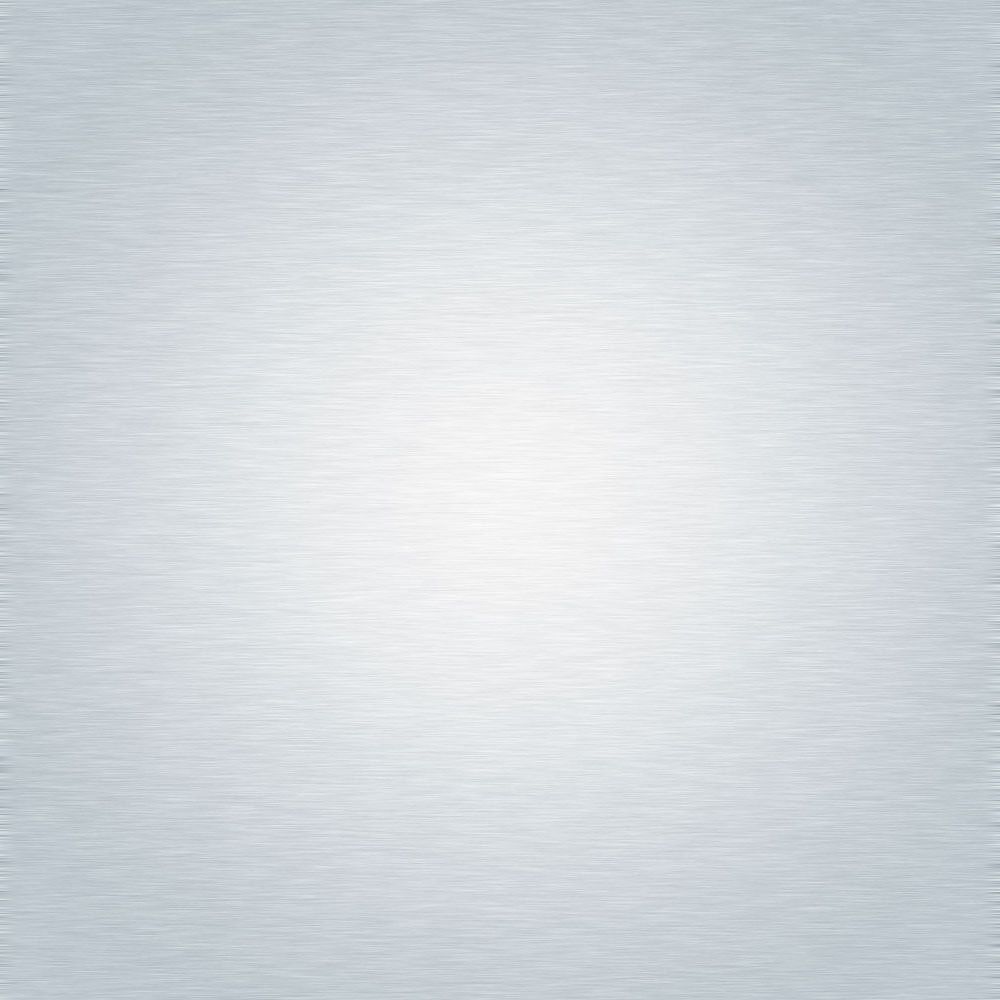

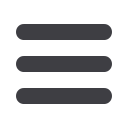

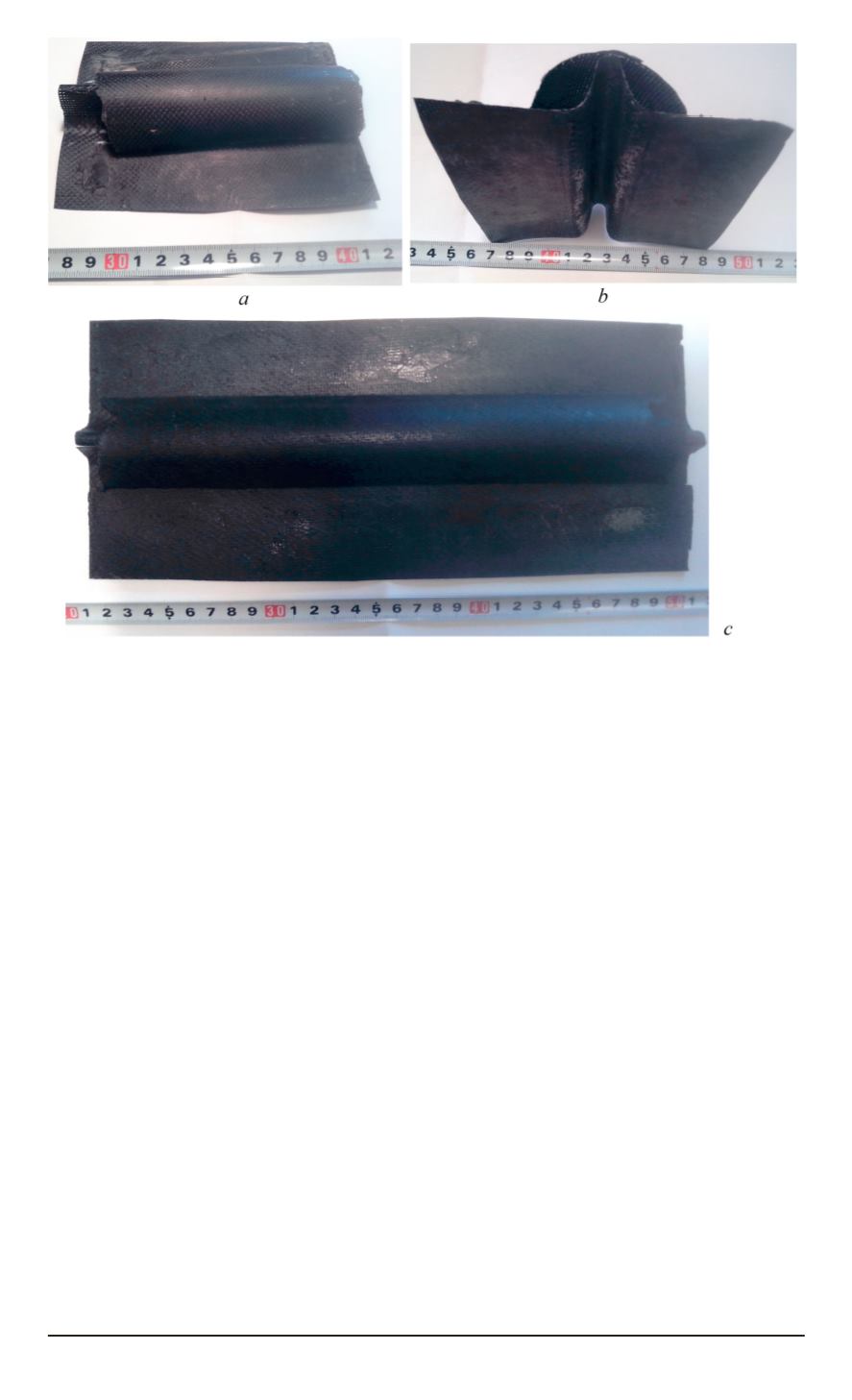

Fig 3. Bi-stable CFRP test beams

Basic principles of current design were tested by fabricating two test

bi-stable beams made of CFRP, short and long, with the same cross-section

as shown in Fig. 3.

The dimensions of test samples were 155 mm

×

110 mm

×

24 mm and

298 mm

×

125 mm

×

24 mm for short and long version respectively. Cross-

section of each beam was formed with semicircular upper mold with 24

mm radius and lower one with 8 mm wide fold and 20 mm height. The

thickness of the walls was 0.2 mm. Comfiber carbon plain 80 g/m

2

fabric

and Axon EPOLAM 2017 resin was used for the fabrication of test samples

with vacuum infusion process. The choice of 80 g/m

2

fabric is due to the

fact, that the use of 100 or 200 g/m

2

fabric for the test samples, while

allowing it to keep shape perfectly, introduces excessive rigidity, which

leads to cracking or failure during flattening. The use of fabric with density

less than 80 g/m

2

leads to an excessive decrease of stiffness and inability

to hold shape. The choice of the resin was due to the similar reasons.

The next step of experimental validation was the folding testing. The

sample was slowly flattened and rolled on the round bobbin. The folded

and fixed test article is shown in Fig. 4.

During folding tests, the phenomenon was observed, referred further

as self-locking of bi-stable composite beam. Simply flat surface supported

52 ISSN 0236-3941. Вестник МГТУ им. Н.Э. Баумана. Сер. “Машиностроение”. 2015. № 1