Uniform Tension: the Problem and the Solution

ISSN 0236-3941. Вестник МГТУ им. Н.Э. Баумана. Сер. Машиностроение. 2017. № 5

23

One of the ways to create a stress state almost exactly like all-round uniform ten-

sion is applied along three mutually perpendicular axes uniform tensile forces. The

stress state arising from this can be called a uniform three axial tension (UTAT). The

description of the device and the sample for the project are described in the article. In

conclusion, the results of tests of samples of plexiglass and carbon-carbon composite

material (CCCM) are given.

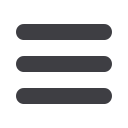

1. The author was offered a device which

allowed to test in three axial tension using a

standard testing machine [4] and a sample for

such tests [5]. Detailed description the device is

in [4]. The device is shown in Fig.1.

The advantage of the device is that the load

increases proportionally on all three axes. If

you set the same move at the top and bottom of

the device (Fig. 1) which is possible with mod-

ern test machines, the center of the sample re-

mains stationary.

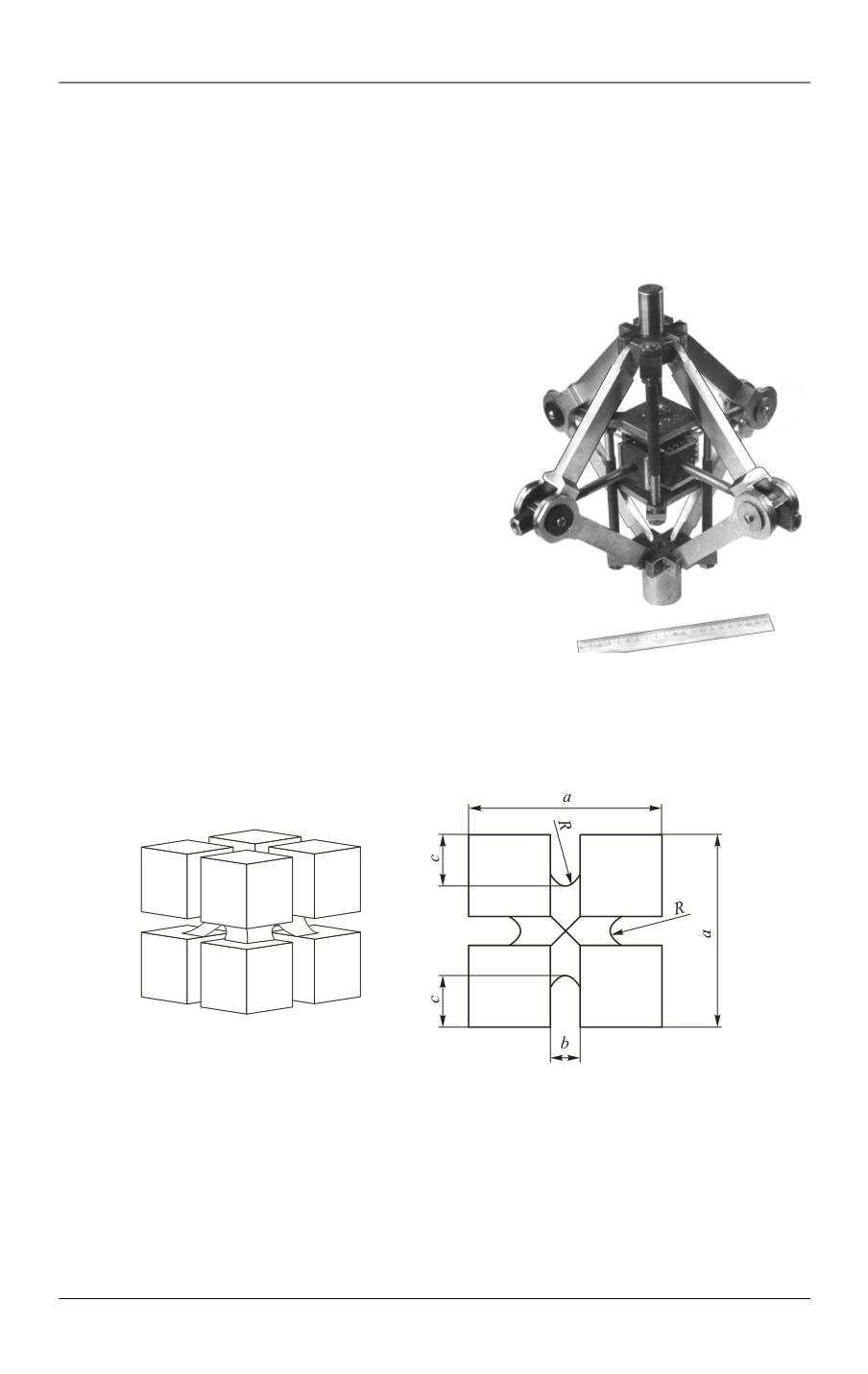

The sample for uniform all-round tension

[5] is developed in the form of a cube, having in

the middle of each edge of the groove (Fig. 2).

The grooves restrict the area of comprehensive

stretching. As shown by the results of the ex-

periments, the fracture surface passes through

this area and does not affect the part of the sample in contact with the grip.

Fig. 2.

The sample for the three axial tension

The shape and size of the sample chosen from the following simplified considera-

tions.

Width

b

and depth

c

of the grooves in the sample should be such that the failure

of the specimen occurred in the middle part of the tensile stress, not shear due to the

impact of grippers of device.

Fig. 1.

Device for three axial tension