investment, maintenance cost and environment impact will be significantly

reduced, and consequently the price of these products could be reduced as

well. Furthermore, because of the co-production, the “peak and valley” of

each product (especially power generation) could be adjusted more easily

according to the demand.

5. “Open” and highly flexible. Under the concrete circumstance of

China, in the coal abundant areas, polygeneration system is quite beneficial.

It could be implemented step-by-step or phase-by-phase according to the

technical advancement and the availability of capital investment. For

example, for the first phase, only power, heat and methanol could be co-

produced, some more other products could be arranged later when financial

situation is improved.

Fig. 3 only shows the preliminary framework of polygeneration. The

detailed material flow, energy flow, information flow and multi-target

(technology, economics, resources utilization, environment) optimization

for each related subsystems should be carried out in the future through

sophisticated study of complex systems and taking the local concrete

conditions into account.

A Quantitative Example of the Benefit of Polygeneration System.

The base case for comparison is the stand-alone production of power,

heat, methanol and syngas by conventional power plant, industrial boilers,

traditional technology for methanol production, and coal gasifiers corres-

pondingly. The outputs are respectively 400 MW

e

, 400 MW

th

and 400 MW

equivalent.

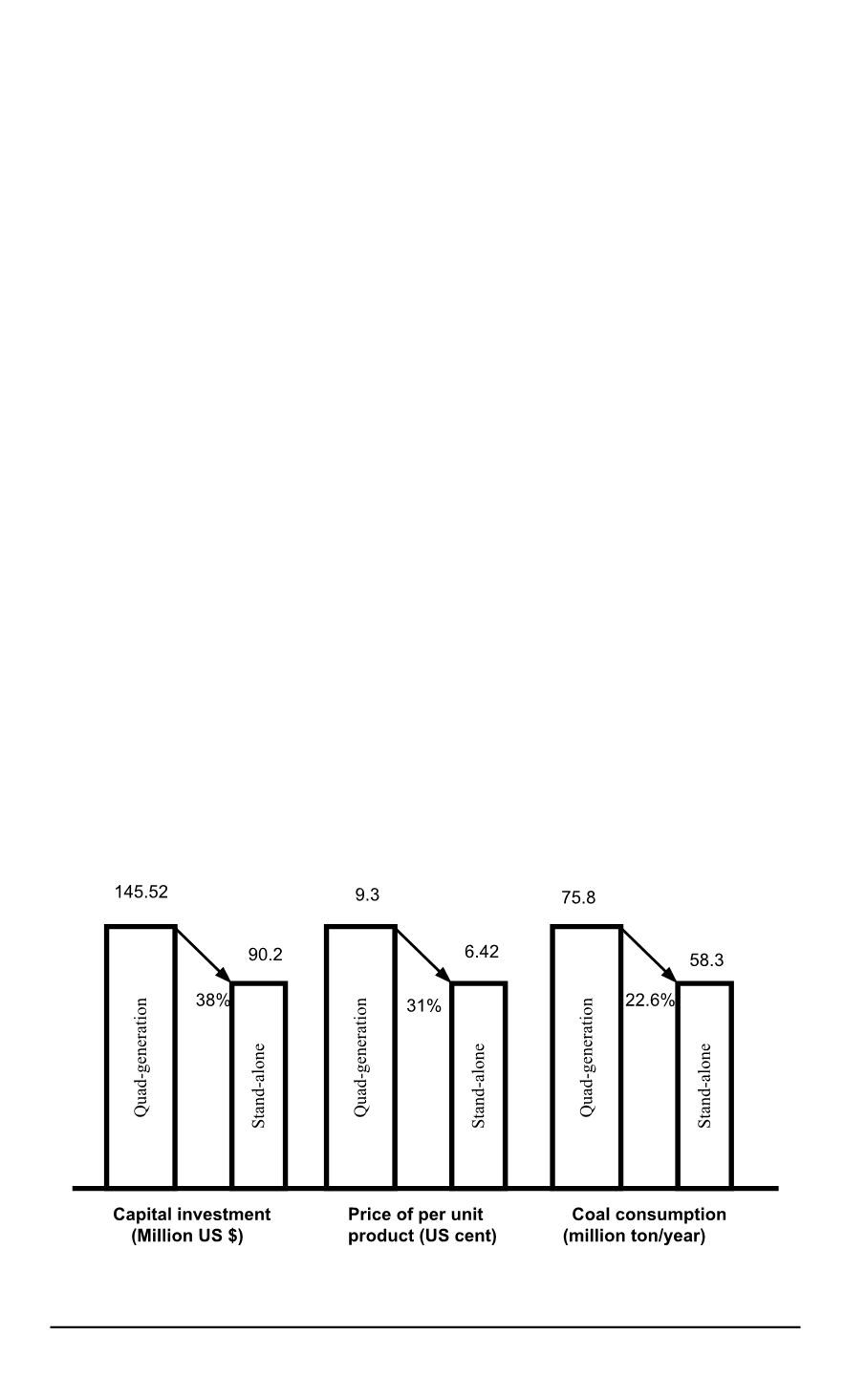

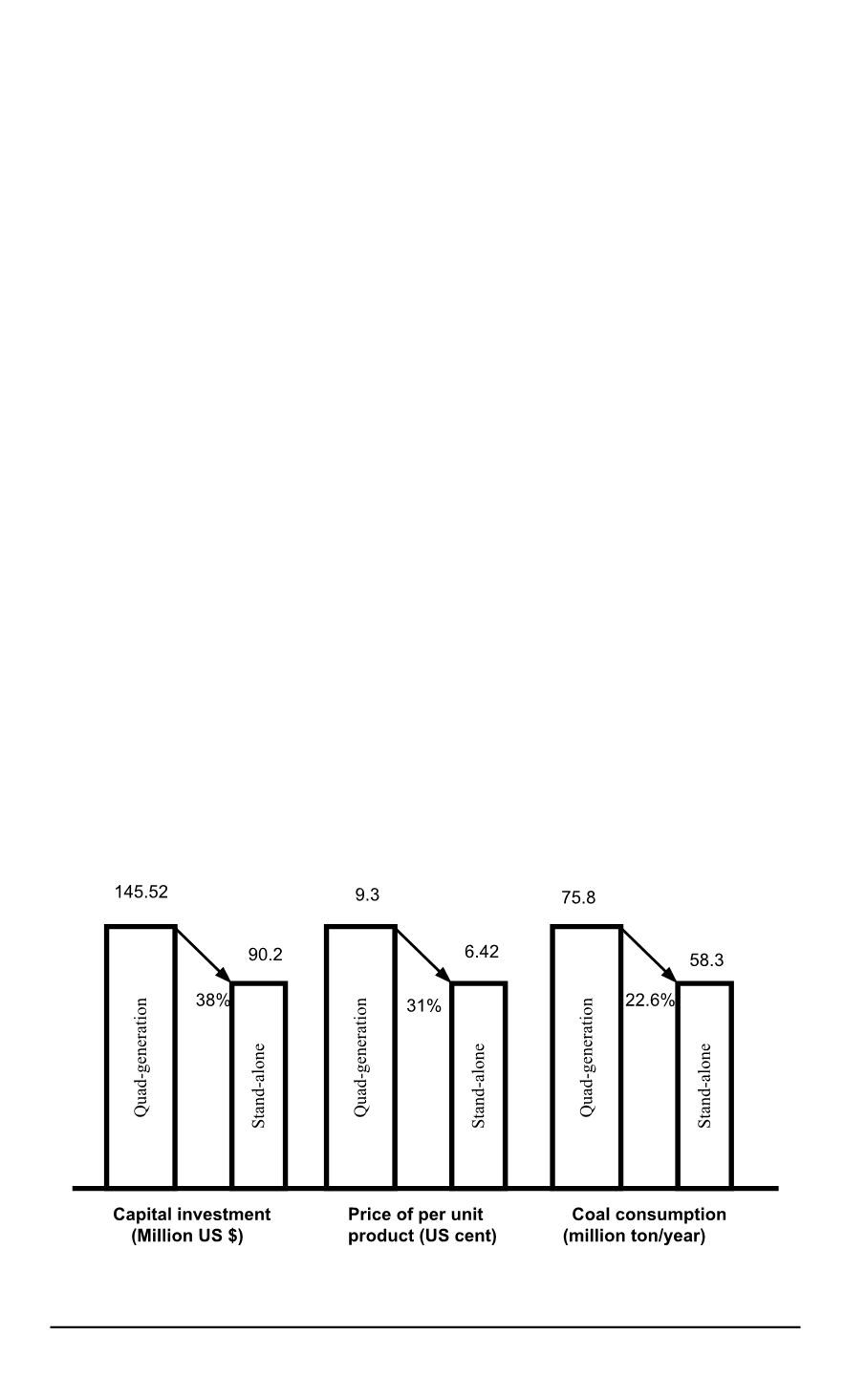

Compared with stand-alone production, quad-generation of these four

products leads to the following benefits: reductions of capital investment

by 38 percent, cost for unit energy by 31 percent and coal consumption by

22.6 percent [3] (see Fig. 4).

Fig. 4. Benefits of investment, energy consumption and environment for quad-

generation

ISSN 0236-3941. Вестник МГТУ им. Н.Э. Баумана. Сер. “Машиностроение”. 2006. № 1 115